24 Nov, 04

Warehouse Safety Management Guide: Best Practices for Enhancing Safety

Warehouse safety is crucial for protecting employees, minimizing accidents, and ensuring smooth operations. Implementing effective safety management practices not only fosters a secure working environment but also enhances overall productivity. This guide outlines key best practices for warehouse safety management, highlighting the role of turnover boxes and shelving systems in promoting safety.

1. Conduct Regular Safety Audits

Regular safety audits help identify potential hazards and ensure compliance with safety regulations. Key steps include:

Checklist Creation: Develop a comprehensive safety checklist covering areas such as equipment maintenance, fire safety, and employee practices.

Hazard Identification: Routinely inspect the warehouse for hazards such as cluttered walkways, improperly stored materials, or malfunctioning equipment.

2. Implement Proper Storage Practices

Effective storage practices are vital for maintaining a safe warehouse environment. Utilizing turnover boxes and shelving systems can significantly enhance safety:

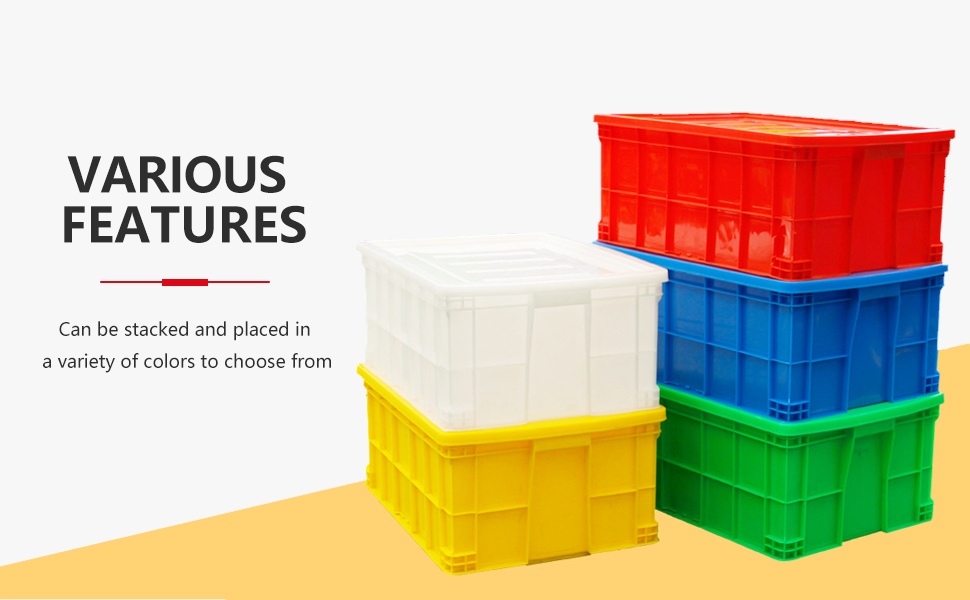

Use of Turnover Boxes: Stackable turnover boxes help keep items organized and off the floor, reducing tripping hazards. Ensure that boxes are stored within easy reach to minimize the need for stretching or climbing.

Shelving Systems: Utilize sturdy shelving systems that can safely hold inventory. Ensure that shelves are not overloaded, as this can lead to collapses and injuries. Implement proper labeling to indicate weight limits.

Example: A distribution center replaced traditional shelving with modern, heavy-duty shelving units, resulting in fewer accidents and improved organization.

3. Train Employees on Safety Protocols

Educating employees on safety protocols is essential for minimizing accidents. Implement the following strategies:

Safety Training Programs: Provide regular safety training sessions covering topics such as proper lifting techniques, equipment operation, and emergency procedures.

Emergency Response Drills: Conduct drills to prepare employees for emergencies, such as fire evacuations or hazardous material spills.

4. Enhance Material Handling Practices

Safe material handling is crucial for preventing injuries. Best practices include:

Use of Proper Equipment: Equip employees with appropriate tools for moving heavy items, such as pallet jacks, forklifts, and conveyor systems. Ensure that operators are trained and certified.

Ergonomic Considerations: Encourage ergonomic practices, such as using lifting aids and team lifting for heavy or awkward items.

5. Maintain Clear Walkways and Access Areas

Cluttered walkways can lead to slips, trips, and falls. Maintain clear access paths by:

Organizing the Warehouse: Regularly declutter aisles and work areas. Use turnover boxes to store items neatly and label areas clearly to promote organization.

Signage: Install clear signage indicating walkways, emergency exits, and hazardous areas to guide employees safely.

6. Implement Safety Signage and Alerts

Visual reminders play a crucial role in promoting safety awareness. Consider the following:

Safety Signs: Use clear and visible safety signs throughout the warehouse to remind employees of safety protocols and potential hazards.

Color Coding: Employ color coding for different zones (e.g., red for danger, green for safe areas) to enhance awareness and understanding of safety practices.

7. Regular Maintenance of Equipment

Regular maintenance of equipment is essential for safety. Ensure that:

Routine Inspections: Schedule regular inspections and maintenance for forklifts, shelving, and other equipment to prevent malfunctions that could lead to accidents.

Repairs: Address any identified issues promptly to ensure a safe working environment.

Conclusion

Implementing effective warehouse safety management practices is essential for protecting employees and maintaining operational efficiency. By conducting regular audits, utilizing turnover boxes and shelving systems, training employees, enhancing material handling practices, maintaining clear walkways, and ensuring equipment safety, businesses can create a safer working environment.

Prioritizing safety not only reduces the risk of accidents but also fosters a culture of awareness and responsibility, ultimately leading to improved productivity and employee morale.

Related Posts

24

Nov 04Optimizing Warehouse Space and Efficiency: The Perfect Combination of Turnover Boxes and Shelves

In modern warehouse management, how to efficiently use space and improve work efficiency is an important issue faced by every enterprise. Whether it is a small business or a large warehouse, choosing the right storage tools is crucial. This article will explore how turnover boxes and shelves can become a powerful assistant in warehouse management, helping you optimize inventory space and improve overall efficiency.

24

Nov 03Applications of Smart Warehouse Management Systems: Enhancing Efficiency with Modern Technology

In today's competitive business landscape, efficient warehouse management is crucial for optimizing operations and improving customer satisfaction. The advent of smart warehouse management systems (WMS) and technologies such as RFID (Radio Frequency Identification) has revolutionized inventory management. This article explores how these technologies enhance warehouse efficiency and provides product recommendations to facilitate their implementation.