24 Nov, 04

Optimizing Warehouse Space and Efficiency: The Perfect Combination of Turnover Boxes and Shelves

In modern warehouse management, how to efficiently utilize space and enhance operational efficiency is a critical challenge faced by every business. Whether for small enterprises or large warehouses, selecting the right storage tools is essential. This article explores how turnover boxes and shelves can be valuable allies in warehouse management, helping you optimize inventory space and improve overall efficiency.

1. Turnover Boxes: Flexible and Efficient Storage Solutions

Turnover boxes are indispensable tools in modern warehousing. They not only effectively classify and store items but also offer the following advantages:

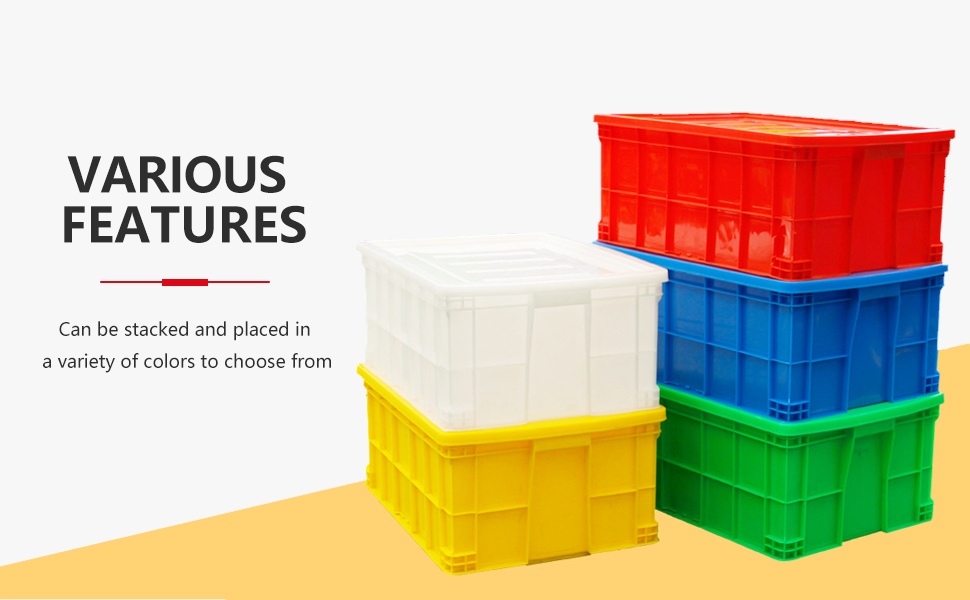

Maximized Space Utilization: The design of turnover boxes allows them to be stacked, effectively using the vertical space in your warehouse. This means you can store more products in limited floor space, reducing wasted space.

Simplified Item Management: By using color coding or labeling, turnover boxes can easily identify different types of products, making inventory management more efficient. Employees can quickly locate the items they need, increasing picking speed and reducing errors.

Enhanced Operational Efficiency: Utilizing turnover boxes simplifies the inbound and outbound processes, reducing the time items spend moving within the warehouse, thereby boosting overall work efficiency. This is especially beneficial during peak times, allowing you to respond quickly to market demands.

2. Shelves: The Backbone of Warehouse Space

Shelves are the "skeleton" of the warehouse. An appropriate shelving layout can not only improve storage efficiency but also ensure safety and convenience:

Diverse Options: There are various types of shelves available in the market based on different storage needs, including heavy-duty shelves, medium-duty shelves, and lightweight shelves. This allows businesses to choose the right shelving according to the characteristics of their products.

Rational Layout: By optimizing shelf layout, placing high-turnover items near the entrance can significantly reduce picking time and enhance operational efficiency. An effective shelving layout can also improve employee work experience and reduce operational risks.

Expanded Storage Capability: Modern shelving systems allow for vertical expansion of storage space, enabling you to accommodate more goods even within limited floor space, thereby increasing storage capacity.

3. The Perfect Match of Turnover Boxes and Shelves

Combining turnover boxes with shelves provides robust support for your warehouse management:

Categorized Storage: Use turnover boxes to classify different types of products stored on shelves for quick retrieval and picking.

Increased Storage Flexibility: By using adjustable shelf heights, you can easily rearrange turnover boxes based on inventory changes, ensuring that your storage space is always optimized.

Enhanced Operational Safety: A good combination of turnover boxes and shelves can effectively reduce the risk of accidents during handling, improving warehouse safety.

4. Conclusion

In a competitive market environment, optimizing warehouse space and increasing operational efficiency are crucial. Turnover boxes and shelves, as two key tools, can help you achieve these goals. Whether you need to improve your existing warehouse management or are building a new facility, the combination of these two will provide you with powerful support.

If you are interested in our turnover boxes and shelves, feel free to contact us for more information. Let’s work together to optimize your warehouse management and enhance your business's competitiveness!

Related Posts

24

Nov 04The Importance of Turnover Boxes in Inventory Management

In today's fast-paced business environment, effective inventory management is crucial for ensuring operational efficiency and customer satisfaction. Among the various tools available to optimize inventory processes, turnover boxes stand out as an essential component. This article explores the significance of turnover boxes in inventory management, highlighting their advantages and best practices for implementation.

24

Nov 03Choosing the Right Type of Shelving: A Comprehensive Guide

In the realm of warehouse management, selecting the appropriate shelving type is crucial for optimizing storage efficiency and ensuring smooth operations. Different shelving systems cater to varying needs based on product weight, size, and turnover rates. This article provides a comprehensive analysis of different types of shelving, including heavy-duty, medium-duty, light-duty, and combination shelving, along with their characteristics and suitable applications.