24 Nov, 03

Applications of Smart Warehouse Management Systems: Enhancing Efficiency with Modern Technology

In today's competitive business landscape, efficient warehouse management is crucial for optimizing operations and improving customer satisfaction. The advent of smart warehouse management systems (WMS) and technologies such as RFID (Radio Frequency Identification) has revolutionized inventory management. This article explores how these technologies enhance warehouse efficiency and provides product recommendations to facilitate their implementation.

1. Understanding Warehouse Management Systems (WMS)

Warehouse Management Systems (WMS) are software solutions designed to support and optimize warehouse operations. They provide real-time visibility into inventory levels, streamline order fulfillment, and enhance overall productivity. Key features of WMS include:

Inventory Tracking: WMS allows for real-time monitoring of stock levels, ensuring accurate inventory records and reducing the risk of stockouts or overstocking.

Order Management: Automates order processing and prioritizes shipments based on delivery schedules, improving order accuracy and reducing lead times.

Data Analytics: Offers insights into inventory turnover rates, picking efficiency, and storage utilization, enabling data-driven decision-making.

Product Recommendation: Consider investing in a cloud-based WMS like Fishbowl or Odoo. These systems provide flexibility, scalability, and integration with other business applications.

2. Leveraging RFID Technology

RFID technology enhances inventory management by enabling automatic tracking of goods throughout the supply chain. RFID tags, attached to products or pallets, communicate with RFID readers to provide real-time data on inventory movement. Key benefits include:

Increased Accuracy: RFID reduces manual counting errors, ensuring accurate inventory records.

Faster Processing: With RFID, multiple items can be scanned simultaneously, significantly speeding up receiving, picking, and shipping processes.

Improved Visibility: Real-time tracking allows businesses to monitor inventory levels and locations, facilitating better stock management.

Product Recommendation: Implement RFID solutions from providers like Zebra Technologies or Impinj. These companies offer comprehensive RFID systems, including tags, readers, and software for seamless integration into your warehouse operations.

3. Optimizing Picking and Packing Processes

Smart warehouse management systems, combined with RFID technology, streamline the picking and packing processes. Automated systems can prioritize orders and direct employees to the most efficient picking routes. Key strategies include:

Batch Picking: WMS can group similar orders, allowing warehouse staff to pick multiple orders simultaneously, thus reducing time spent on each order.

Zone Picking: By dividing the warehouse into zones, WMS can assign specific picking tasks to different employees, optimizing labor efficiency.

Product Recommendation: For efficient picking, consider picking carts with integrated scanners, such as those from Rubbermaid or Groupe Lacasse, which facilitate quick and organized order fulfillment.

4. Enhancing Inventory Visibility and Control

Integrating WMS with RFID technology improves overall inventory visibility and control. Businesses can monitor stock levels in real time, adjust inventory based on demand fluctuations, and optimize reorder points. This proactive approach minimizes excess inventory and reduces carrying costs.

Product Recommendation: Utilize inventory dashboards provided by software like NetSuite or TradeGecko. These tools offer visual insights into inventory levels, trends, and forecasts, empowering businesses to make informed decisions.

5. Conclusion

The application of smart warehouse management systems and RFID technology is transforming inventory management. By leveraging these modern technologies, businesses can enhance efficiency, accuracy, and visibility in their warehouse operations.

Investing in a robust WMS and RFID solutions, along with tools that support picking and inventory visibility, will empower organizations to optimize their warehouse processes, reduce operational costs, and ultimately improve customer satisfaction. As the logistics landscape continues to evolve, embracing these technologies will be key to staying competitive in the market.

Related Posts

24

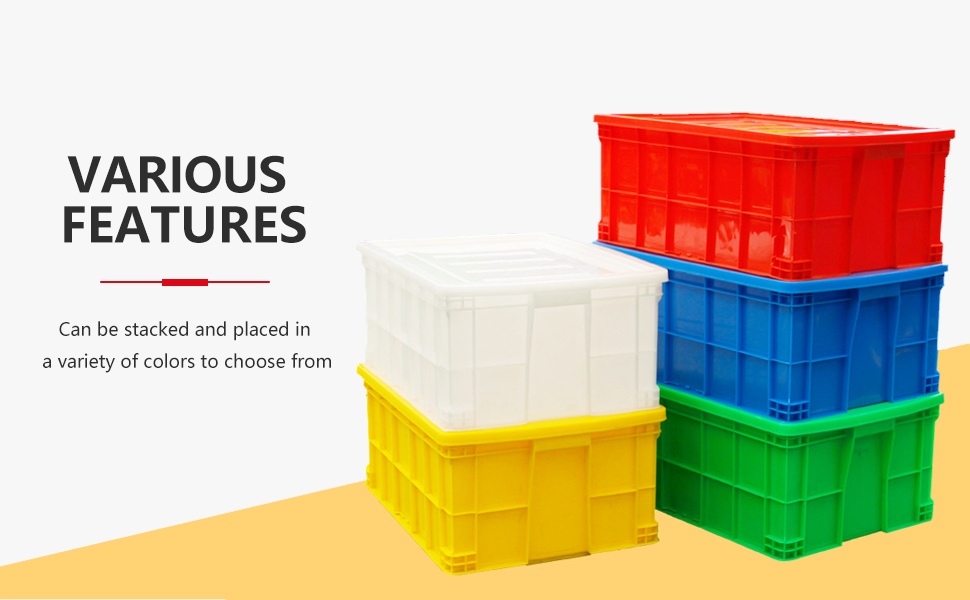

Nov 04Optimizing Warehouse Space and Efficiency: The Perfect Combination of Turnover Boxes and Shelves

In modern warehouse management, how to efficiently use space and improve work efficiency is an important issue faced by every enterprise. Whether it is a small business or a large warehouse, choosing the right storage tools is crucial. This article will explore how turnover boxes and shelves can become a powerful assistant in warehouse management, helping you optimize inventory space and improve overall efficiency.

24

Nov 04Seasonal Inventory Management: Adapting Strategies for Peak and Off-Peak Periods

Effective inventory management is crucial for businesses to thrive, especially during seasonal fluctuations in demand. Understanding how to adjust inventory strategies during peak and off-peak periods can significantly enhance operational efficiency and customer satisfaction. This article analyzes how to adapt inventory management strategies based on seasonal demand, highlighting the flexibility of turnover boxes and shelving systems.