24 Nov, 04

Seasonal Inventory Management: Adapting Strategies for Peak and Off-Peak Periods

Effective inventory management is crucial for businesses to thrive, especially during seasonal fluctuations in demand. Understanding how to adjust inventory strategies during peak and off-peak periods can significantly enhance operational efficiency and customer satisfaction. This article analyzes how to adapt inventory management strategies based on seasonal demand, highlighting the flexibility of turnover boxes and shelving systems.

1. Understanding Seasonal Demand

Seasonal demand refers to the variations in product demand that occur at different times of the year. For example, retailers often experience higher demand during holidays or special events, while certain products may see reduced sales during off-peak times. An effective inventory management strategy must account for these fluctuations to prevent overstocking or stockouts.

2. Adjusting Inventory Levels

Peak Season Strategies:During peak seasons, businesses should increase their inventory levels to meet higher demand. This requires careful forecasting based on historical sales data, market trends, and promotional activities. Key strategies include:

Increasing Stock Quantity: Order additional inventory to ensure adequate supply, focusing on high-turnover items.

Utilizing Turnover Boxes: Implement turnover boxes for efficient storage of high-demand items. These boxes facilitate quick access and organization, allowing staff to swiftly fulfill orders.

Off-Peak Season Strategies:Conversely, during off-peak seasons, businesses should consider reducing inventory levels to minimize carrying costs. Strategies include:

Inventory Reduction: Analyze slow-moving items and reduce orders accordingly, focusing on maintaining only essential stock.

Reorganizing Storage: Use flexible shelving systems to optimize space. Adjustable shelving can be reconfigured to accommodate reduced inventory while maintaining easy access to remaining products.

3. Implementing Flexible Storage Solutions

Turnover Boxes:Turnover boxes offer exceptional flexibility, making them ideal for seasonal inventory management. During peak seasons:

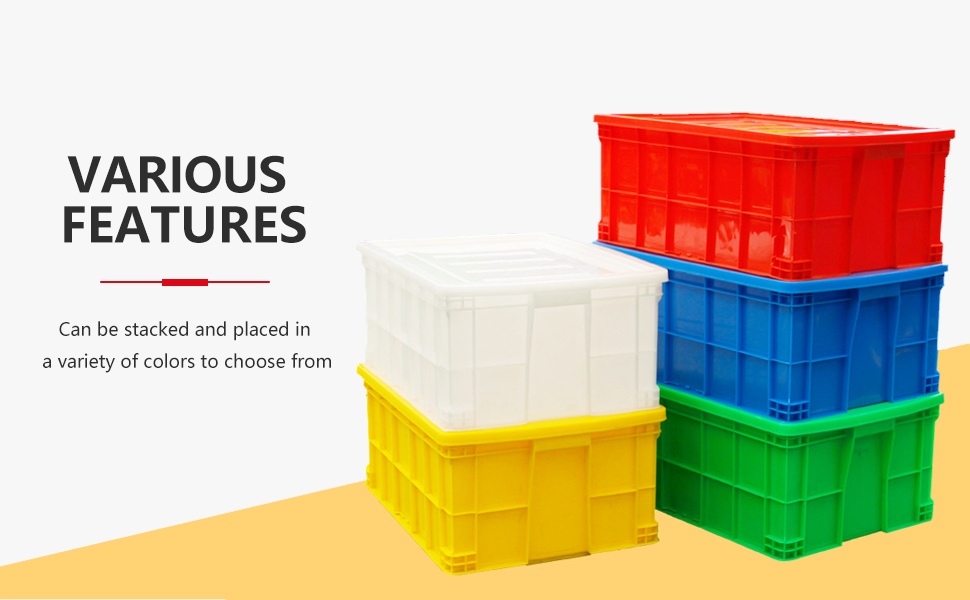

Stackable Design: Utilize the stackable nature of turnover boxes to maximize vertical space and accommodate increased stock.

Clear Labeling: Label boxes clearly to ensure quick identification and retrieval of popular items.

During off-peak seasons:

Consolidation: Empty or consolidate turnover boxes for slow-moving items, freeing up space for high-demand products.

Easy Reconfiguration: Quickly adjust the organization of turnover boxes as inventory needs change, ensuring efficient use of storage space.

Shelving Systems:The right shelving systems are essential for adapting to seasonal changes. During peak periods:

High-Density Shelving: Implement high-density shelving to store more items in a smaller footprint, improving picking efficiency.

Dynamic Layouts: Create dynamic layouts that prioritize high-turnover products in easily accessible locations.

In off-peak seasons:

Rearranging Shelves: Take advantage of adjustable shelving to reorganize based on reduced stock, optimizing space and accessibility.

Space-Saving Solutions: Utilize lighter shelving options for slow-moving items to keep the warehouse organized without unnecessary clutter.

4. Effective Inventory Tracking and Management Tools

Utilizing inventory management software is vital for tracking stock levels, sales trends, and seasonal fluctuations. Advanced tools can help businesses:

Forecast Demand: Analyze historical data to predict upcoming seasonal trends, allowing for timely inventory adjustments.

Monitor Performance: Track sales performance in real-time to respond quickly to changes in demand during both peak and off-peak seasons.

Conclusion

Adapting inventory management strategies for seasonal fluctuations is essential for maximizing efficiency and customer satisfaction. By leveraging the flexibility of turnover boxes and shelving systems, businesses can optimize their storage solutions to meet varying demands throughout the year.

Implementing effective strategies during peak and off-peak seasons, along with utilizing advanced inventory tracking tools, will empower businesses to navigate seasonal challenges successfully, ensuring they remain competitive and responsive in the marketplace.

Related Posts

24

Nov 04Reducing Warehouse Costs: Optimizing Storage Tools and Processes

In an increasingly competitive market, managing warehouse costs effectively is vital for maintaining profitability. By optimizing storage tools and processes, businesses can significantly reduce operational expenses. This article explores various strategies to lower warehouse costs while enhancing efficiency and productivity.

24

Nov 04The Importance of Turnover Boxes in Inventory Management

In today's fast-paced business environment, effective inventory management is crucial for ensuring operational efficiency and customer satisfaction. Among the various tools available to optimize inventory processes, turnover boxes stand out as an essential component. This article explores the significance of turnover boxes in inventory management, highlighting their advantages and best practices for implementation.