24 Nov, 04

Techniques for Optimizing Warehouse Space

In a rapidly evolving market environment, warehouse management faces numerous challenges, including space shortages, rising costs, and inefficiencies. Optimizing warehouse space not only significantly enhances storage capacity but also reduces operational costs and improves overall business efficiency. Effective space management strategies can help companies respond more flexibly to market changes and strengthen their competitive edge.

For instance, an e-commerce company successfully increased its storage capacity by 20% by redesigning its warehouse layout. They positioned high-turnover items near the entrance and utilized stackable shelves and turnover boxes, thereby reducing picking time. This change not only improved operational efficiency but also boosted customer satisfaction, allowing the company to stand out in a competitive market.

Another successful case comes from a manufacturing company that implemented an advanced inventory management system and automation equipment, achieving intelligent management of warehouse space. By monitoring inventory levels in real-time and dynamically adjusting storage locations, they increased warehouse space utilization by 30%. Such optimization strategies enabled the company to respond more quickly to customer demands, lowering inventory costs.

Here are some practical techniques for optimizing warehouse space, allowing you to draw from these success stories and better manage your inventory.

a. Rational Layout

A well-planned warehouse layout is key to space optimization. Consider adopting a “U-shaped” or “L-shaped” layout, positioning shelves close to the entrance to significantly reduce the distance traveled by pickers and enhance work efficiency. For example, a retail company managed to reduce picking time by 15% through layout adjustments.

b. Utilize Vertical Space

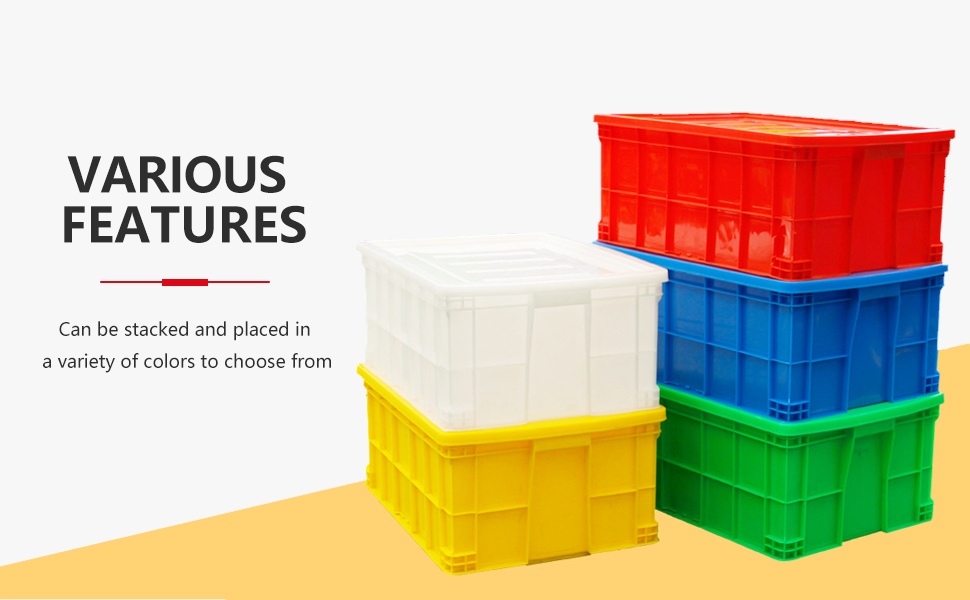

Making full use of the warehouse height is another important method for increasing storage capacity. Choosing stackable shelves and turnover boxes allows you to store more goods in a limited floor area, helping to reduce space waste. For instance, a pharmaceutical company utilized high-rise shelves in its warehouse, successfully boosting storage capacity by 40%.

c. Categorized Storage

Classifying inventory by product type, turnover frequency, and size enhances retrieval efficiency. Ensuring that high-turnover items are placed in easily accessible locations can streamline your workflow. For example, a food distribution company reduced product search time and improved operational efficiency through categorized storage.

d. Regular Evaluation and Adjustment

Regularly reviewing inventory and layout allows for flexible responses to changing business needs, enabling timely adjustments to maintain high operational efficiency. A furniture retailer successfully identified space waste issues through quarterly evaluations and implemented optimizations that significantly improved warehouse efficiency.

By implementing these strategies, you can significantly enhance warehouse space utilization, reduce operational costs, and ultimately boost overall business efficiency.

Related Posts

24

Nov 03Strategies to Improve Picking Efficiency: Best Practices for Streamlining Operations

In the fast-paced world of warehousing and logistics, efficient picking processes are essential for meeting customer demands and optimizing operations. By implementing best practices, businesses can design picking workflows that reduce operational time and enhance productivity. This article outlines key strategies to improve picking efficiency in warehouses.

24

Nov 03Applications of Smart Warehouse Management Systems: Enhancing Efficiency with Modern Technology

In today's competitive business landscape, efficient warehouse management is crucial for optimizing operations and improving customer satisfaction. The advent of smart warehouse management systems (WMS) and technologies such as RFID (Radio Frequency Identification) has revolutionized inventory management. This article explores how these technologies enhance warehouse efficiency and provides product recommendations to facilitate their implementation.